Horizontal Machining Centers Application and Scope in Indian Manufacturing Industries

The Indian manufacturing industry is undergoing a significant transformation driven by advancements in technology and increasing demands for precision and efficiency. Among the many technological innovations shaping this landscape, Horizontal Machining Centers (HMCs) stand out as a game-changer. These machines are revolutionizing the way manufacturers approach production, providing unparalleled capabilities and benefits.

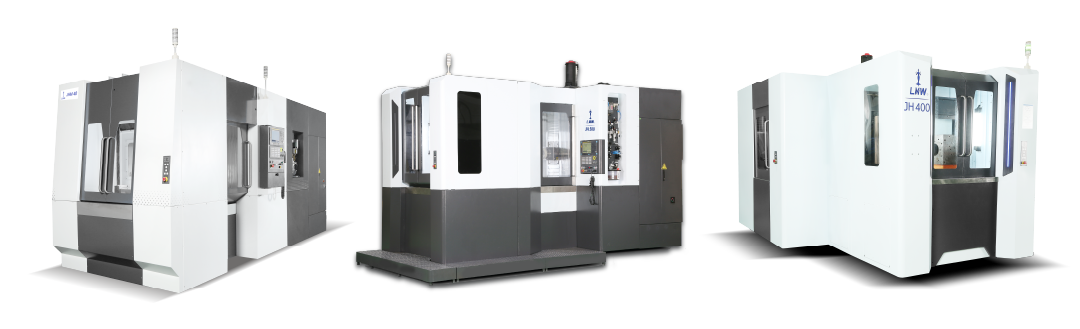

What Are Horizontal Machining Centers?

Horizontal machining centers (HMCs) are advanced CNC (Computer Numerical Control) machines characterized by their horizontal spindle orientation. Unlike vertical machining centers (VMCs), HMCs position the workpiece horizontally, allowing for multi-sided machining with fewer setups. This feature enhances precision, reduces cycle times, and improves overall efficiency.

Key Features of Horizontal Machining Centers

1. Horizontal Spindle Orientation: Allows for gravity-assisted chip evacuation, ensuring a cleaner work area and better surface finishes.

2. Pallet Systems: Equipped with pallet changers that enable simultaneous machining and loading, thereby increasing productivity.

3. High Rigidity: Designed to handle heavy-duty machining with greater stability and reduced vibrations.

4. Multi-Axis Capabilities: Many HMCs support multi-axis operations, providing versatility for complex geometries.

5. Tool and Workpiece Accessibility: Improved access to the workpiece facilitates intricate machining tasks.

Applications of Horizontal Machining Centers

HMCs find applications across a wide range of industries in India, including but not limited to:

Automotive Industry: Production of engine components such as cylinder blocks, crankcases, and transmission housings.

Manufacturing of suspension components and other critical parts requiring high precision.

Aerospace Industry: Machining of complex and lightweight components such as airframe structures, turbine blades, and landing gear components.

Machining of alloys and composites.

Heavy Equipment Manufacturing: Production of large, heavy components like gearboxes, hydraulic parts, and construction machinery components.

General Engineering: Fabrication of tools, moulds, and dies for industries like plastics, rubber, and metal stamping.

Versatile applications in job shops for small to medium batch production.

Energy Sector: Machining of components for wind turbines, thermal power plants.

Advantages of Horizontal Machining Centers

Enhanced Productivity: The ability to perform multiple operations in a single setup reduces downtime and increases throughput.

Improved Accuracy: Minimizing repositioning enhances dimensional accuracy and consistency.

Automation features: Automation features such as pallet changers and tool management systems lower manual intervention.

Optimized Chip Management: Horizontal orientation facilitates efficient chip evacuation.

Cost Savings: Although HMCs have a higher initial investment cost, their long-term benefits in terms of productivity and quality outweigh the expense.

Horizontal machining centers are a vital asset for the Indian manufacturing sector, driving productivity, precision, and global competitiveness. With a supportive ecosystem and strategic investments, HMCs can unlock unprecedented growth opportunities across industries. As India strides toward becoming a global manufacturing powerhouse, the role of advanced machinery like HMCs will be pivotal in shaping its success.