Horizontal Machining Center - JHM 40

- Single piece box construction for optimal structural stability

- Compact Machine with smaller foot print.

- Moving column – Fixed table machining for better accuracies

- High speed rotary pallets for higher productivity.

- Automatic pallet changer (APC) eliminates loading/unloading time.

- Higher rapids

- Compact 40 tool magazine for smooth and high speed indexing

| Description |

Unit |

JHM 40 |

| Capacity |

| X Axis |

mm |

500 |

| Y Axis |

mm |

500 |

| Z Axis |

mm |

500 |

| Spindle center to pallet top |

mm |

100-600 |

| Spindle nose to pallet center |

mm |

100-600 |

| Max. work piece diameter |

mm |

600 |

| Max. work piece length |

mm |

500 |

| Pallet |

| Pallet size |

mm |

400 x 400 |

| No of Pallets |

nos |

2 |

| Pallet change |

type |

Rotary |

| Maximun indexing angle |

deg |

1° |

| Pallet change time |

sec |

15 |

| Maximum load on pallet |

kgs |

400 |

| Spindle |

| Spindle speed |

rpm |

6000 |

| Spindle bore taper |

type |

BT 40 |

Spindle motor power

( Cont. /Inter.) |

kW |

11 / 15 |

Max. Spindle Torque

( Cont. /Inter.) |

Nm |

52.5 / 95.5 |

| Feed system |

| Rapid traverse rate ( X / y / Z ) |

m/min |

48/32/48 |

| Cutting feed rate |

m/min |

10 |

| Dia. x Pitch of ball screw |

mm |

ɸ40 x 16 |

| Automatic Tool Changer |

| No. of tools |

nos |

40 |

| Tool shank configuration |

type |

BT-40 |

| Max. Tool dia with adjacent tool |

mm |

75 |

| Max. Tool dia without adjacent tool |

mm |

140 |

| Max. tool length |

mm |

300 |

| Max. tool weight |

kgs |

7 |

| Tool change time (tool to tool) |

sec |

3 |

| Machine Size |

| L x B x H |

mm |

2800 x 5800 x 2730 |

| weight |

kgs |

9000 |

| CNC System |

| Controller |

|

Fanuc 0i-MF |

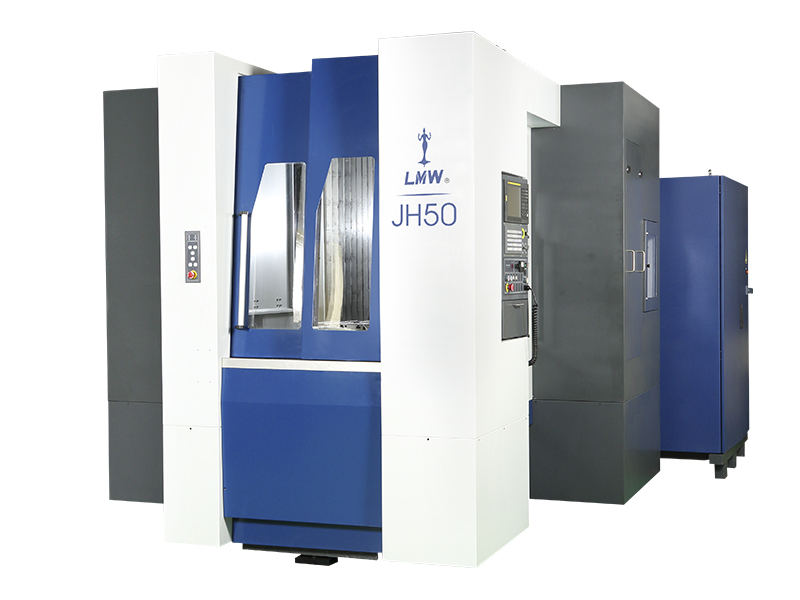

Horizontal Machining Center - JH 50

- Integral Spindle Motor

- Coolant Through Spindle

- Integral Torque motor rotar y table

| Description |

Unit |

JH 50 |

| Travels |

| X/Y/Z Axis |

mm |

730 x 560 x 560 |

| Spindle center to Pallet top |

mm |

150-710 |

| Spindle nose to Pallet center |

mm |

150-710 |

| Max. Work piece diameter |

mm |

1000 |

| Max. Work piece length |

mm |

700 |

| Table/Rotary Pallet |

| Pallet size |

mm |

500 x 500 |

| No. of Pallets |

Nos |

1 |

| Pallet Change |

Type |

- |

| Maximum Indexing Angle |

Deg |

1° |

| Pallet Change Time |

Sec |

- |

| Max. Load on Pallet |

Kgs |

600 |

| Spindle |

| Spindle Speed |

rpm |

4000 |

| Spindle Bore taper |

Type |

BT50 |

| Spindle Motor Power(Cont./ inter) |

kW |

15/18.5 |

| Max. Spindle Torque (Cont. / Inter.) |

Nm |

215/420 |

| Feed system |

| Rapid Traverse rate (X/Y/Z) |

m/min |

36/36/36 |

| Cutting feed rate |

m/min |

10 |

| Dia. X Pitch of ball screw |

mm |

ɸ40 x 12 |

| Automatic Tool Changer |

| No. of Tools |

Nos |

24 |

| Tool Shank Configration |

Type |

BT50 |

| Max tool dia with adjacent tool |

mm |

125 |

| Max tool dia without adjacent tool |

mm |

200 |

| Max tool length |

mm |

300 |

| Max. Tool weight |

Kgs |

15 |

| Tool change time (tool to tool) |

Secs |

6 |

| Machine Size |

| L x B x H |

mm |

4970x4860x3440 |

| Weight |

Kgs |

12000 |

| CNC system |

| Controller |

|

Fanuc 0i MF |

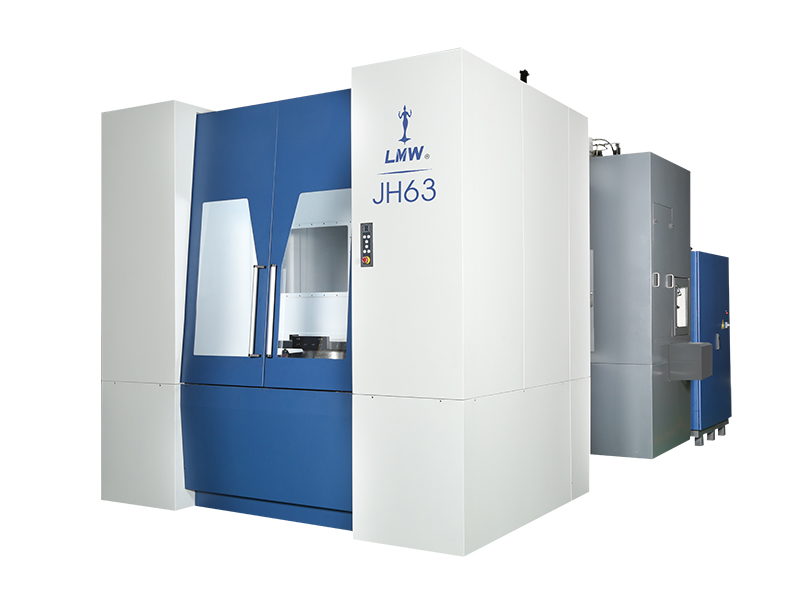

Horizontal Machining Center - JH 63

- BT50 Tool Shank System.

- Rigid Monoblock Bed Structure.

- Coolant through Spindle.

- Rotar y table with built in Torque motor.

- High torque Spindle.

- In-built screw conveyor for chip disposal.

| Description |

Unit |

JH 63 |

| Travels |

| X/Y/Z Axis |

mm |

1020X800X1000 |

| Spindle center to Pallet top |

mm |

150-950 |

| Spindle nose to Pallet center |

mm |

150-1150 |

| Max. Work piece diameter |

mm |

1200 |

| Max. Work piece length |

mm |

1000 |

| Table/Rotary Pallet |

| Pallet size |

mm |

630x800 |

| No. of Pallets |

Nos |

2 |

| Pallet Change |

Type |

Rotary |

| Maximum Indexing Angle |

Deg |

1° |

| Pallet Change Time |

Sec |

16 |

| Max. Load on Pallet |

Kgs |

800 |

| Spindle |

| Spindle Speed |

rpm |

4000 |

| Spindle Bore Taper |

Type |

BT 50 |

| Spindle Motor Power (Cont. / Inter.) |

Kw |

18.5 / 22 |

| Max. Spindle Torque (Cont. / Inter.) |

Nm |

465 / 788 |

| Feed system |

| Rapid traverse rate (X/Y/Z) |

m/min |

30/30/30 |

| Cutting feed rate |

m/min |

10 |

| Dia. X Pitch of ball screw |

mm |

Ø50 x 16 |

| AUTOMATIC TOOL CHANGER |

| No. of Tools |

Nos |

40 |

| Tool Shank Configration |

Type |

BT50 |

| Max. Tool dia with adjacent tool |

mm |

125 |

| Max. Tool dia without adjacent tool |

mm |

250 |

| Max. Tool length |

mm |

400 |

| Max. Tool weight |

Kgs |

20 |

| Tool change time (tool to tool) |

Secs |

3 |

| Machine Size |

| L x B x H |

mm |

8200 x 3900 x 3410 |

| Weight |

Kgs |

21000 |

| CNC system |

| Controller |

|

Fanuc 0i-MF |

copyright © lakshmi machine works limited. all rights reserved

info@lmwcnc.com

info@lmwcnc.com