Horizontal Lathe - LR30 C

| Desciption | Unit | LR30 C |

|---|---|---|

| Capacity | ||

| Swing Over bed | mm | 680 |

| Chuck dia. Max | mm | 304 |

| Max. Turning dia | mm | 470 |

| Max. Turning Length | mm | 400 |

| Admit Between Centres | mm | - |

| Spindle | ||

| Spindle nose | type | A2-8 |

| Hole through spindle | mm | 77 |

| Spindle speed | rpm | 3500 |

| Spindle motor power | kW | 15 / 18.5 |

| Feed | ||

| Inclination of Carriage | Deg | 45° to Horizontal Plane |

| Travel X - Axis | mm | 260 |

| Travel Z - Axis | mm | 500 |

| Rapid traverse rate X/Z axes | m/min | 20 / 24 |

| Turret | ||

| No. of stations | nos. | 8 |

| Tool shank size | mm | 25 x 25 |

| Max. Boring bar dia | mm | 50 |

| Turret Indexing | type | Hydraulic |

| Turret Indexing | Sec | 1.5 |

| Tailstock | ||

| Quill dia | mm | NA |

| Quill stroke | mm | NA |

| Quill taper | - | NA |

| CNC System | ||

| Controller | Type | Fanuc / Siemens |

| Machine Size | ||

| L x B x H | mm | 3015 x 1615 x 2240 |

| Weight | Kg | 5000 |

Material Removal Rate (MRR)

| Description | Unit | LR30 C |

|---|---|---|

| Diameter | mm | 151 |

| Cutting Speed | m/sec | 200 |

| Spindle Speed | rpm | 422 |

| DOC | mm | 6 |

| Feed | mm/rev | 0.32 |

| Capacity | cc/min | 384 |

| Spindle Lord | % | 95 |

Horizontal Lathe - LR30T L7

Computerised numerically controlled 2-axes Lathe, complete with hydraulic turret, coolant unit, hydraulic unit and other standard accessories suitable for operation on 415V +10%, 3 phase, 50 cycle AC supply and capable of per forming a variety of machining operation such as straight turning, drilling, boring, contouring with linear and circular interpolation, internal and external threading etc.

The machine base is of rigid, sufficient wide torsion-free box type construction.

Bed, saddle and all major casting is of high grade FG 300 grey cast iron, duly stress relieved. The machine bed is 45 degree slant, so as to avoid chip accumulation at the front side.

The saddle and headstock are mounted on the same plane to minimize effect of thermal distor tions on the component accuracies.

Hardened and ground box guideways are used for movement of both the axes. The guideways and ball screw is properly lubricated by centralised unit.

| Desciption | Unit | LR30T L7 |

|---|---|---|

| Capacity | ||

| Swing Over bed | mm | 680 |

| Chuck dia. Max | mm | 304 |

| Max. Turning dia | mm | 470 |

| Max. Turning Length | mm | 700 |

| Admit Between Centres | mm | 820 |

| Spindle | ||

| Spindle nose | type | A2-8 |

| Hole through spindle | mm | 77 |

| Spindle speed | rpm | 3500 |

| Spindle motor power | kW | 15 / 18.5 |

| Feed | ||

| Inclination of Carriage | Deg | 45° to Horizontal Plane |

| Travel X - Axis | mm | 260 |

| Travel Z - Axis | m/min | 760 |

| Rapid traverse (X/Z) - Axes | m/min | 20 / 24 |

| Turret | ||

| No. of stations | nos. | 8 |

| Tool shank size | mm | 25 x 25 |

| Max. Boring bar dia | mm | 50 |

| Turret Indexing | type | Hydraulic |

| Turret Indexing | Sec | 1.5 |

| Tailstock | ||

| Quill dia | mm | 85 |

| Quill stroke | mm | 80 |

| Quill taper | Type | MT-3 |

| CNC System | ||

| Controller | Type | Fanuc / Siemens |

| Machine Size | ||

| L x B x H | mm | 3015 x 1615 x 2240 |

| Weight | Kg | 5200 |

Material Removal Rate (MRR)

| Description | Unit | LR30T L7 |

|---|---|---|

| Diameter | mm | 151 |

| Cutting Speed | m/sec | 200 |

| Spindle Speed | rpm | 422 |

| DOC | mm | 6 |

| Feed | mm/rev | 0.32 |

| Capacity | cc/min | 384 |

| Spindle Lord | % | 95 |

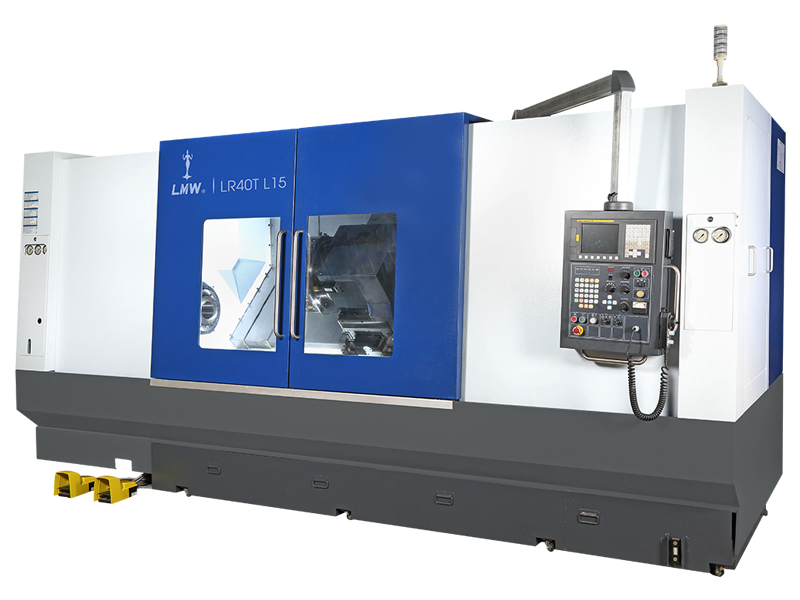

Horizontal Lathe - LR40T L15

- Robust machine construction to demonstrate its best cutting performance

- Rigidity structure for outstanding cutting capabilities.

- Box slide ways for higher vibration damping performance.

- 45 deg slant bed improves cutting capabilities

- High-torque spindle motor provides power for heavy stock removal

- Roller & Angular bearings to improve stability during heavy cutting

- larger through spindle hole

- High-precision, quick-change hydraulic turret

- Hook on type tail stock to support heavy work piece.

- large diameter ball-screw to provide high rigidity for high feed rates

- Broader field of vision & Ergonomic Design with Double-Panel safety window

| Desciption | Unit | LR40T L15 |

|---|---|---|

| Capacity | ||

| Swing Over bed | mm | 760 |

| Chuck dia. Max | mm | 381 |

| Max. Turning dia | mm | 600 |

| Max. Turning Length | mm | 1500 |

| Admit Between Centres | mm | 1640 |

| Spindle | ||

| Spindle nose | type | A2-11 |

| Hole through spindle | mm | 113 |

| Spindle speed | rpm | 1900 |

| Spindle motor power | kW | 18.5 / 22 |

| Feed | ||

| Inclination of Carriage | Deg | 45° to Horizontal Plane |

| Travel X - Axis | mm | 330 |

| Travel Z - Axis | m/min | 1620 |

| Rapid traverse (X/Z) - Axes | m/min | 20 / 24 |

| Turret | ||

| No. of stations | nos. | 8 |

| Tool shank size | mm | 32 x 32 |

| Max. Boring bar dia | mm | 60 |

| Indexing time (per station) | sec | 1.5 |

| Turret Indexing | Type | Hydraulic |

| Turret Indexing Time | Sec | 1.5 |

| TAILSTOCK | ||

| Quill Diameter | mm | 120 |

| Quill Stroke | mm | 120 |

| Quill Stroke | Type | MT-6 |

| CNC System | ||

| Controller | type | Fanuc / Siemens |

| Machine Size | ||

| L x B x H | mm | 4950 x 2475 x 2500 |

| Weight | Kg | 11000 |

Horizontal Lathe - LR30T L12

| Desciption | Unit | LR30T L12 |

|---|---|---|

| Capacity | ||

| Swing Over bed | mm | 680 |

| Chuck Size | mm | 304 |

| Max. Turning dia | mm | 470 |

| Max. Turning Length | mm | 1201 |

| Admit Between Centres | mm | 1462 |

| Spindle | ||

| Spindle nose | type | A2-8 |

| Hole through spindle | mm | 77 |

| Spindle speed | rpm | 3500 |

| Spindle motor power (Cont./15 min) | kW | 15/18.5 |

| Feed system | ||

| Inclination of Carriage | Deg | 45° to Horizontal Plane |

| Travel X - Axis | mm | 262 |

| Travel Z - Axis | m/min | 1260 |

| Rapid traverse (X/Z) - Axes | m/min | 20 / 24 |

| Turret | ||

| No. of stations | nos. | 8 |

| Tool shank size | mm | 25 x 25 |

| Max. Boring bar dia | mm | 50 |

| Turret Indexing | Type | Hydraulic |

| Turret Indexing Time | Sec | 1.5 |

| Tailstock | ||

| Quill dia | mm | 85 |

| Quill stroke | mm | 120 |

| Quill taper | Type | MT -4 |

| CNC system | ||

| Controller | Type | Fanuc / Siemens |

| Machine size | ||

| L x B x H | mm | 4405 x 2100 x 2498 |

| Machine Weight (Approx) | kg | 7500 |

info@lmwcnc.com

info@lmwcnc.com